Categories

Recent Posts

No recent posts found

Act fast to enjoy discounts of up to 30%! Don't let this limited-time offer slip away!

GET A QUOTELimited time offer. Don't miss out!

In the custom boxes market, the use of high-quality material is a crucial factor in the determination of the boxes’ longevity and the protection of the packed items. There are several types and sub-types of packaging materials available for custom boxes. Each material has its unique qualities and capacities to withstand external rigors.

At PremiumCustomBoxes, we provide our customers with a huge range of paper-based materials for their boxes so that they can choose the most appropriate option considering their product requirements. From kraft to cardboard, corrugation, and rigid all materials are available to us. You can select all the aspects of your custom packaging materials such as coating thickness, add-ons, etc by consulting our manufacturing staff and figuring out what suits you.

Today, the trend in custom packaging has increased because to create an identity in the market and to get the attention of customers brands have to present their products in an attractive and alluring way. For this, not only an attractive look but also a quality material is necessary. Considering the current wave of climate change, it has become mandatory to use sustainable material for boxes, and here comes customized packaging material that you can select as per your budget, product requirement, brand value, and so on. Some of the qualities of these materials are:

When you opt for the option of customization then you can select the material from a huge range. Some of the materials are quite thin and are only useful for retail boxes that are used for a short duration. In the same manner, you can get the boxes as strong as wood material. Some of the common materials that you can get from our company are:

Cardstock is a kind of ubiquitous material that is widely used in the box manufacturing industry. Custom cardboard boxes have impressive durability and are not expensive because they are produced with recyclable material. There are two subtypes of cardboard:

Cardstock has 12 pt to 24 pt thickness which makes it an ideal solution for retail boxes. This material is lightweight and a versatile option for printing due to its smooth surface. From our company you can get unique add-on options that include, embossing, debossing, foil stamping, and spot UV. To protect the outer layer we have the option of gloss, matte, soft-touch, UV, and aqueous coating.

Duplex board is a two-layered subtype of cardboard. Only one side of the material is printable. The one layer of this material is 8 pt to 16 pt. This material is used for the manufacturing of food boxes at affordable rates. Window patching, inserts, embossing, and debossing are the common add-on options for this stock with gloss, matte, and water-based varnishes on the surface. You can also get wax-coated boxes from inside that will keep the boxes moisture-free and give an excellent barrier to heat.

We get kraft material by processing softwood fiber with a minimal amount of chemical treatment. Kraft is a 100 percent biodegradable material and the best option to get the attention of climate-conscious customers. Custom kraft boxes are made of two main types of kraft, namely:

Natural kraft is one of the least processed subtypes of kraft. Due to minimal processing, this material contains residual fiber that gives it a rustic look. The thickness of natural kraft ranges from 1 pt to 4 pt. You can select this material for the packaging of your organic products, such as CBD boxes. This stock has a brown color, durability, recyclability, and biodegradable nature. With the help of ribbon, die cutting, spot UV, matte, and water base varnish we provide a smooth surface to this material.

White kraft is among the bleached custom packaging materials. This has the same thickness as that of natural kraft which is 1 to 4 pt. Due to the white color, the printing becomes way easier as compared to the brown one, nonetheless, bleaching reduces the durability of the material to a small extent. Foil stamping, embossing, gloss, matte soft touch, and aqueous coating are the additional options that we provide for this stock.

Corrugated material has flutes that create a cushioned effect around the material keeping the product secure and warm (in the case of food items). Corrugated material has several flute sizes and different numbers of fluted layers. Custom corrugated boxes from A to F flutes are available with the following number of layers:

In single-walled boxes, the fluted layer consists of 3mm – 5mm thickness. This material is suitable for custom shipping boxes due to its lightweight. By adding inserts the protection of shipped products is enhanced. Similar to others, this material is also coated with gloss, matte, and UV coatings.

With a thickness of 5mm – 7mm this corrugated material has extra durability and strength. So when you have to ship high-end materials then you can select this option. For pizza slice boxes double walled corrugated material is preferred as it keeps the pizza hot. Corrugated material can not be embossed or debossed but we can add inserts and apply coatings on it.

Triple-wall corrugated material is available with a fluted layer of 7mm – 10mm. Due to its three layers, this material has the maximum durability and gives marvelous protection to fragile products. Water-based varnish, UV coating, matte, gloss any of the available coatings can be applied to them.

Chipboard is a low-quality material that is not a common option to manufacture boxes in the USA. Nonetheless, chipboard fiber is used to produce thick and hard layers of rigid material. Gray chipboard has a thickness of 0.5 mm to 2 mm. This is a low-cost material and can also be used for internal structures of packaging and is not coated normally. On the other hand, there is a clay-coated form of chipboard that has 1 – 3 mm thickness, and a smooth surface which allows easy printing. With foil stamping and spot UV, we can use this material to manufacture printed packaging material.

Rigid material is one of the most durable and premium materials used to manufacture custom boxes. For luxurious items such as custom jewelry boxes, watch boxes, PR packaging, etc. Rigid material is manufactured using chipboard fiber which is compressed to produce a sturdy material with a wood-like consistency. The premiums of custom rigid boxes are enhanced with the help of gloss, matte, spot UV, and aqueous coating. Moreover, we add some of the additional elements such as ribbon, inserts, embossed or debossed designs, etc to produce premium quality boxes such as custom electronic boxes.

Some of the custom luxury packaging boxes are manufactured with rigid material of 1.5 mm to 3 mm and are highly sturdy. These boxes are non-collapsable, pre-assembled, and commonly used as custom gift boxes. With the addition of magnetic closures, foil stamping, and coatings like silk screen an enticing appearance to the boxes can be provided.

Natural Bux board is stiff, has a brown color, is recyclable, and has an eco-friendly nature. Products that require protection with a natural look are usually packed in boxes made with bux board. Nonetheless, due to the coarse surface, this material is not easy to print. For printing, the material is bleached and coated with matte, gloss, or clay coatings that make the surface smooth and allow high-quality prints.

PremiumCustomBoxes has more than a decade of experience in the box manufacturing industry which is why we are aware of the changing trends in packaging and customers’ expectations from them. Our experienced team, high-end raw materials, and advanced technology help the customers to accelerate their business growth. We give affordable packaging services with unlimited customization options. With sturdy and sustainable packaging material we turn brands’ dream packaging into reality. So get a quote and enjoy the most valuable packaging experience.

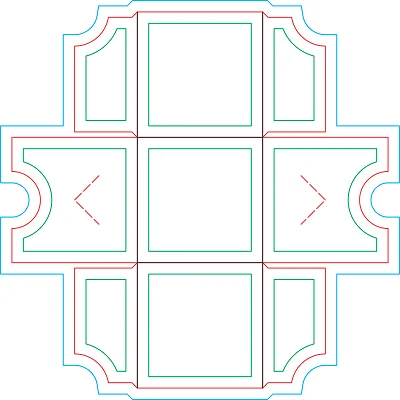

Preparing artwork for various purposes, whether it's for print, digital media, or other applications, requires attention to detail and adherence to specific guidelines. Here is a general artwork preparation guide that you can follow:

Indicates the cut at its final size.Important artwork and text should be placed at least 0.125 inches inside of the cutting line.

Indicates where the bleed line is located. Any artwork which goes to the cutting line should be extended to the bleed line to get a seamless print.

Indicates where artwork and text should safely be placed inside. As a industry standard, all artwork should at least be placed 0.125 inches away from the cutting lines unless your design in intentional.

Perforation line refers to paper that is punched with very small holes to allow the paper to be torn and folded easily.

Indicated where the product is to be folded.

Start by browsing our extensive range of box styles and designs. Whether you're in the market for something simple and classic or intricate and bespoke, we've got a multitude of options to suit your needs.

Once you've chosen a box style, it's time to make it uniquely yours. Upload your design or collaborate with our in-house design team to craft a packaging solution that resonates with your brand's aesthetic and vision.

Our platform allows you to pick from a variety of materials, be it eco-friendly options, premium finishes, or durable structures. Enhance the tactile experience with finishes like matte, gloss, embossing, or specialty textures.

Before we move to production, we'll send you a digital proof or a physical sample upon request. This ensures you're 100% satisfied with the design and materials chosen. Review, make any necessary changes, and give us the green light when you're ready.

Once you've approved the design, our team gets to work. With state-of-the-art machinery and a dedicated workforce, we ensure that each box is crafted to perfection, adhering to the highest quality standards.

With our efficient logistics network, we guarantee timely deliveries. As your boxes are packed and prepared for shipment, we'll provide tracking details to keep you informed every step of the way. Sit back and wait for your premium packaging to arrive at your doorstep.

Are you looking forward to investing in our brand but have several concerns? Do you have ambiguity about our custom box services? If yes then you can contact our customer care representative and get all your queries answered in less than a day. Our diligent team is available for your service all around the clock. You can simply fill in the form on the website, email us on the provided email, or you can directly call us at the given number.

Get a Quote Call Us !

No recent posts found